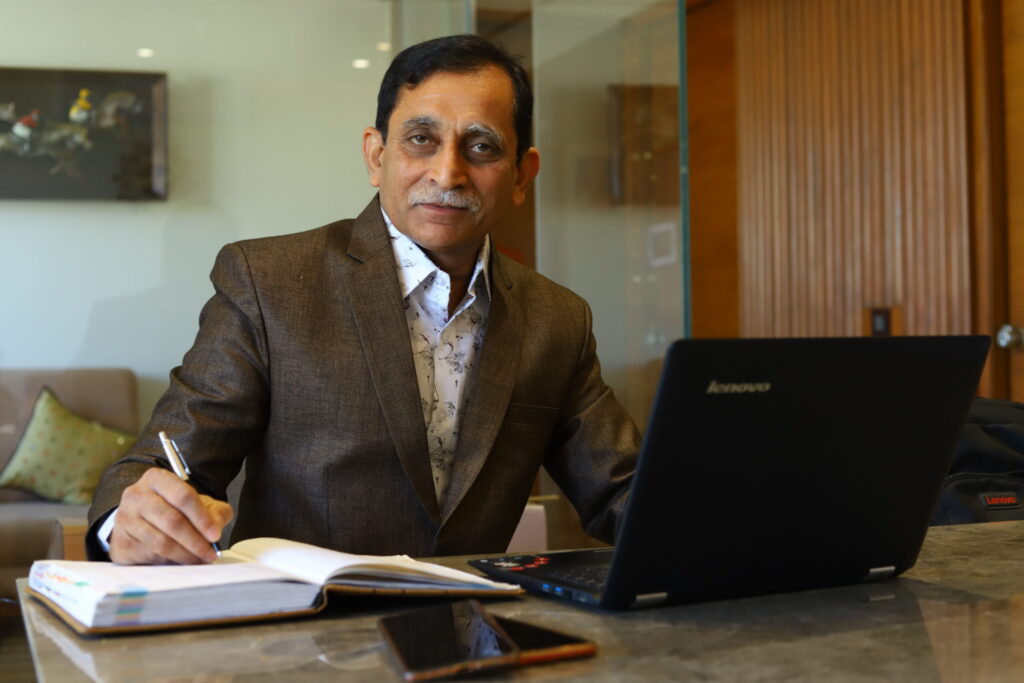

In an exclusive interaction, Vijay Patel, Plant Head, of SKAPS India, shares with Ganesh Kalidas(Author at Textile Magazine) the company’s strategic decisions in geotextiles in India which have led it to stand head and shoulders above the competition. Its successful partnership with Prashant Group underscores the trust factor they share mutually.

Conceptualized and established in 1995 in the US by Perry Vyas, who hails from Gujarat, SKAPS Industries today has a market presence in more than 60 countries. Since its inception, SKAPS Industries has become synonymous with geosynthetics. These include woven, nonwoven, geocomposite, geonet, geomembrane, PP fiber, and fiberglass fabrics used in building infrastructure with environmental advantages. SKAPS set foot in India in 2005 at Ahmedabad, and the company produces 75 million square yards of woven fabric a year from its Indian manufacturing plants. Elaborates Vijay Patel, Plant Head, SKAPS India: “We have nearly the entire range of geotextiles including woven, nonwoven and geocomposites, geonet and geo liners.”

“We have, in total, 13 manufacturing lines for making nonwoven, geocomposite, and geomembrane products, eight for nonwoven, three for geocomposites, and two for geomembranes. Then we have knitting and weaving sections for fiberglass. Further, we make Hydrotex™ which is an engineered fabric to pump concrete in two layers of fabric to help control and slop protection. It is also used to line the channels and can be used in underwater pipelines and dams and in strengthening shorelines from storm damage. We are currently using this in a pilot project to repair Narmada canals,” he adds. SKAPS Hydrotex™ is high-strength polyester and can be custom-made too.

Production Capacity

SKAPS Industries boasts five manufacturing plants in India and the US, besides one in Brazil. It exports majorly to the US and also to Europe. The company has continuously been upgrading and adding capacities and will soon establish a PET foam project which will see an investment of Rs 150-180 crore. Meanwhile, the highly efficient team at SKAPS India has ensured there was little disruption in operations on account of the pandemic in 2020 despite the workforce being inaccessible due to the lockdown for a brief time. Shares Patel: “Within a couple of months after the lockdown was imposed last year, the government gave the go-ahead to special economic zones and export-oriented units to resume production processes. The best part was that our sales figures from last year have been even better than those of previous years.”

SKAPS – Prashant Gamatex Partnership

SKAPS India has been associated with Prashant Group since 2006 for procuring warping machines. Patel praises and says, “Prashant Group had a joint venture with West Point Industries, USA. They supply sizing and warping machines, warping creel, and denim preparation machinery, among others. The unrolling creel of the machine was designed by West Point, USA but developed and supplied by Prashant West Point.” Today, all four warping machines at SKAPS India meant for geotextiles have been procured from Prashant Gamatex and Prashant WestPoint. Undoubtedly, Patel is a satisfied customer of Prashant Group because of its excellent after-sales service.

He explains: “The team at Prashant Group listens to our challenges and any suggestions we have regarding improving the functioning of their machines. We see our partnership carrying into future projects as well because Prashant Group matches our views and vision regarding quality. They have been able to cater to our requirements highly competently, and we feel that this will continue to be so in the future too.” And that is where the key to the USP of SKAPS India lies. With robust support from Prashant Group in the form of machines, SKAPS India delivers quality to its customers. According to Patel, they always strive hard to ensure customer satisfaction, and their loyal customers know about it too.

SKAPS India Vision

The leadership at SKAPS India is highly ambitious. If the current turnover of SKAPS India is about Rs 500 crore, the company is convinced it easily can more than double the figure by 2025. Patel elaborates confidently: “We will be adding a PET project with an investment of up to Rs 180 crore. Additionally, we plan to set up a manufacturing line for fiberglass. So, together all these will give us the fillip and scope to increase our capacity.”

Geo Textiles – Key to Development

The geotextiles segment is poised for a bright future in India since they are much sought after in construction projects for their high reliability in bestowing lifespan to the roads and rail tracks. Patel agrees: “Roads are stronger when geotextiles are used because they well for separation, stabilization, reinforcement, and erosion control. Similarly, in landfill sites, repeated dumping of trash spoils the soil. But geotextiles with geomembranes arrest the contaminants from leaching into the soil and hence keep the surface and groundwater safe.”

The non-permissible properties of the geotextile membrane make them easy to install, providing an environmental-friendly solution. Meanwhile, the socially responsible efforts of SKAPS India have been highly recognized. Last year it was honored with a silver trophy for its performance at the Synthetic Textile Export Promotion Awards function for the year 2018-19, organized by the Synthetic and Rayon Textiles Export Promotion Council.