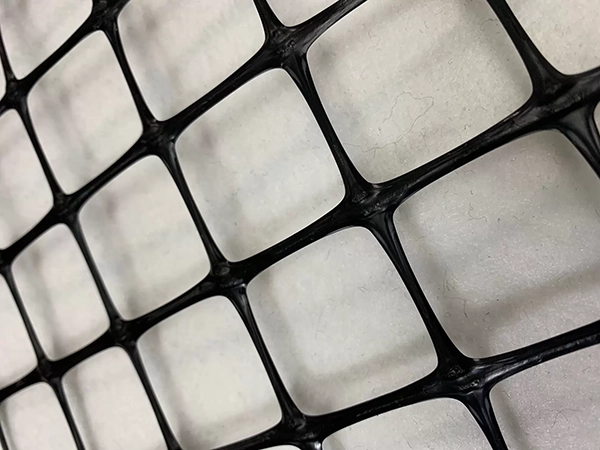

SKAPS BX 1100 is a polypropylene geogrid especially designed for soil stabilization and reinforcement applications. BX 1100 geogrids are manufactured from a unique process of extrusion and punched and drawn to biaxial orientation to enhance tensile properties. SKAPS BX 1100 geogrids feature consistently high tensile strength and modulus, excellent resistance to construction damage, and environmental exposure.

Typical Applications :

Soft soil stabilization, base reinforcement, embankments over soft soils, working platforms, haul roads

| Technical Characteristics | Units | MD Values1 | XMD Values1 |

| Aperture Dimensions2 | mm (in) | 25 (1.06) | 33 (1.45) |

| Minimum Rib Thickness2 | mm (in) | 0.76 (0.03) | 0.76 (0.03) |

| Tensile Strength @ 2% Strain3 | kN/m (lb/ft) | 4.1 (280) | 6.6 (450) |

| Tensile Strength @ 5% Strain3 | kN/m (lb/ft) | 8.5 (580) | 13.4 (920) |

| Ulitimate Tensile Strength3 | kN/m (lb/ft) | 12.4 (850) | 19.0 (1300) |

| STRUCTURAL INTEGRITY | |||

| Junction Efficiency4 | % | 93 | |

| Flexural Stiffness5 | mg-cm | 250,000 | |

| Aperture Stability6 | m-N/deg | 0.32 | |

| DURABILITY | |||

| Resistance to Installation Damage7 | %SC%SW%GP | 95/93/90 | |

| Resistance to Long-Term Damage8 | % | 100 | |

| Resistance to UV Damage9 | % | 100 |

DIMENSIONS AND DELIVERY

The biaxial geogrid shall be delivered to the job site in roll form with each roll individually identified and nominally measuring 3.81m (12.5-FT) in width and 100m (328-FT) in length.

Notes

1. Unless indicated otherwise, the values shown are the minimum average roll value determined in accordance with ASTM D4759-02.

2. Nominal dimensions.

3. Tensile Strength is determined in accordance with ASTM D6637-10 Method A.

4. Load transfer capability determined in accordance with ASTM D7737-11.

5. Resistance to bending force determined in accordance with ASTM D7748-12, using specimens of width two ribs wide, with transverse ribs cut flush with exterior edges of longitudinal ribs, and of length sufficiently long to enable measurement of the overhang dimension.

6. Resistance to in-plane rotational movement measured by applying a 20 kg-cm (2 m-N) moment to the central junction of a 9-IN x 90IN specimen restrained at its perimeter in accordance with US Army Corps of Engineers Methodology for measurement of torsional rigidity.

7. Resistance to loss of load capacity or structural integrity when subjected to mechanical installation stress on clayey sand (SC), well-graded sand (SW), and crushed stone classified as poorly graded gravel (GP). The geogrid shall be sampled in accordance with ASTM D5818-06 and load capacity shall be determined in accordance with ASTM D6637.

8. Resistance to loss of load capacity or structural integrity when subjected to chemically aggressive environments in accordance with EPA 9090 immersion testing.

9. Resistance to loss of load capacity or structural integrity when subjected to ultraviolet light and aggressive weathering in accordance with ASTM D4355-05.